Folding and Blocking Machine

HIEMAC EASYFOLDTM

HIEMAC EASYFOLDTM

Fabric Folding & Blocking Machine for Textiles

FEATURES

- INSTANT THREAD UP

- CONSTANT TENSION BLOCKING

- PERFECT P.E. EDGE GUIDING FOLDING

- SOLID STATE ELECTRONIC DC CONTROL

- FINGERTIP SPEED CONTROL

- QUICK BLOCK REMOVAL

- EXTREMELY SMALL FLOOR SPACE

EFFICIENT AND EASY TO USE

FABRIC UP TO 1800mm WIDE

AUSTRALIAN BUILD QUALITY

SPECIFICATIONS

GENERAL: Free standing machine for unrolling, folding and re-rolling light to

medium weight fabric into precise double folded blocks or rolls as an option. The machine features rapid thread up, easy access and small floor space.

- SUPPORT FRAME: All steel welded and bolted construction.

- DRIVE MOTOR: 240v, 400w DC motor, with infinitely variable speed from zero to 40m per minute.

- ROLL-UP MECHANISM: Gear motor is connected to roll-up shaft with quick release coupling. Roll removal is done by releasing coupling and laying shaft over. Minimum cardboard center is 178mm wide card for blocking or 50mm diameter for round rolls.

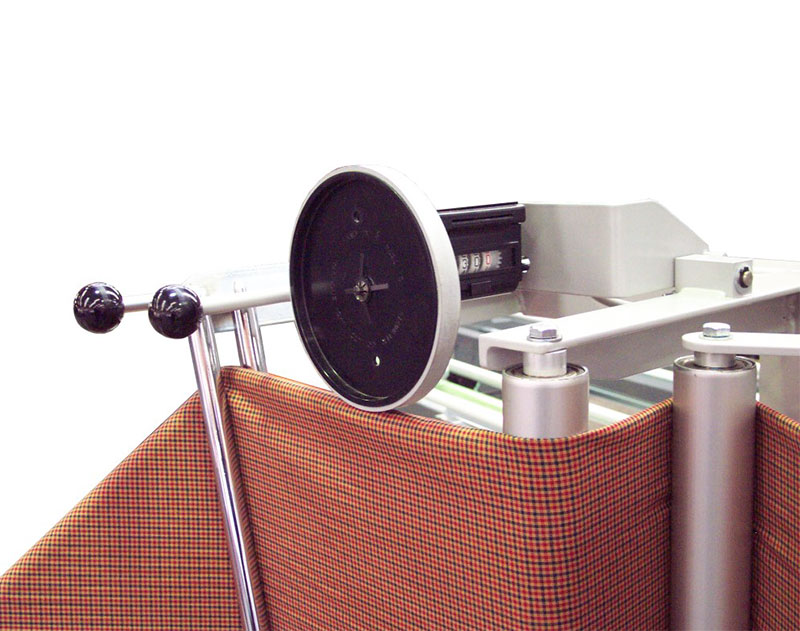

- UNROLL CRADLE: Multi roller cradle, allows quick and efficient thread up time and easy roll replacement. Input roll size 300mm diameter x 1800mm long.

- EDGE GUIDING: Electronic sensors and tracking motor, keep the folded edg-es together for smooth and accurate blocks/rolls.

- LENGTH MEASURING: Accurate Truemeter™ mechanical counter.

- ELECTRONICS: 240v AC 3A solid state drive and push button controls.

![]()

Rear view of folding machine showing tracking cradle

Truemeter™ mechanical counter