Storage Systems for Dry Cleaners & Laundries

AUTOMATED & MANUAL GARMENT HANDLING SYSTEMS FOR DRY CLEANERS & LAUNDRIES

- Bring automation into your dry cleaners or laundry with the latest garment handling technology and modern, efficient equipment.

- Free up your floor space and increase cubic storage capacity.

- Reduce the time and effort in lifting and carrying of garments.

- Decrease the time to process garments and work with a happier, more productive staff.

- Open up your shop and let the light in. Make it brighter, cooler and a better place to work.

- Install the 24-7 Superdry Door and bring many more customers into your shop.

- Convert your dry cleaning shop or laundry into something modern and efficient that you can be proud of.

- Increase productivity and add real dollars to your bottom line.

The Hiemac stainless steel Slick Rail opens up the shop and lets the light in making it brighter, cooler, and a better place to work, note the garments on the carousel overhead

The Hiemac Multi Level Carousels takes the customers apparel up into the unused ceiling area freeing up meters of valuable floor space and giving increased storage capacity at the same time.

Orders are scanned onto the carousel for quick automatic relocation when the customer arrives.

Multi-Level Carousels

The Hiemac bi-lateral carousel is a garment storage and retrieval conveyor which will take your garments off the floor and into the ceiling area saving valuable floor space while automating your shop at the same time. The carousel could pay for itself in 12 months with just the saving in floor space alone.

- Computerize your garment storage and retrieval and bring the garments to the counter when you want them. You never have to remember where the garments are ever again.

- Store your garments in the ceiling area and save valuable floor space.

- Give your shop that space age clean modern look and attract more customers.

- Your staff will stay longer, work better in an efficient, uncluttered, cooler environment.

The carousel is controlled by your POS service counter computer for counter pickups. The 24-7 SuperDry Door (seen in the background) is used for after hours drop off and pick up.

The 24-7 SuperDry Door gives working folk the opportunity to get to your dry cleaning shop after hours, 7 days per week.

Hiemac is closely linked to its associated companies -

| Compassmax | POS software and computer sales |

| DCCS | POS software and computer sales |

| Vinron | POS software and computer sales |

| Fondation Logic | Inventory control and management |

24/7 Autoserve

The 24-7 SuperDry Door allows customers to pick up or drop off garments any time they like.

Supermarkets are open around the clock to service those extra customers, banks have been using automated teller machines for well over 20 years. Today both men and women are often working from 9-5 every day making it difficult to get to those shops that close at 5.30.

The 24-7 SuperDry Door will get these people to your shop.

The touch screen walks the customer through the operations of the 24-7 Door with ease. The screen is also used for advertising your shop.

The Hiemac stainless steel Slick Rail opens up the shop and lets the light in making it brighter, cooler, and a better place to work, note the garments on the carousel overhead

An efficient laundry with screw conveyors, slick rail and speed rail working together. Note the collapsible flat pack carriers on the speed rail.

Screw Conveyors

The Hiemac Screw Conveyors are normally used for automatically transporting hangered garments from pressing to quality control, collating or dispatch. They can lift garments, transport them through the ceiling area, bring them down again and accumulate them at the end of the conveyor.

- Transport garments to their next destination automatically.

- You will never have to sort the pressed garments from the unpressed garments again or lift them off the rail and carry them to the collating area, saving kilometers of back-breaking walking and carrying every day.

- The garments accumulate softly at the end of the conveyor, and do not crush together.

- The Hiemac screw conveyor is made from special Nylon, requires no lubrication, is whisper quiet and extremely robust.

- It is the only screw conveyor that can take wire and plastic hangers simultaneously.

Gear motor drive and emergency lanyard switch

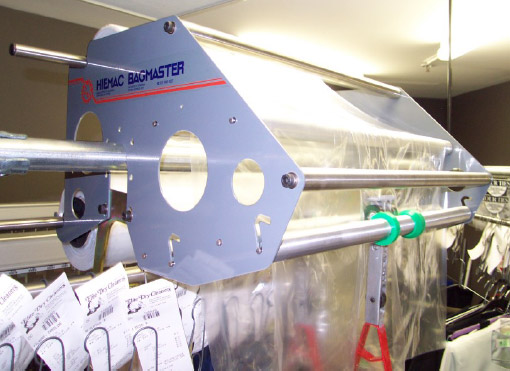

The Bagmaster fits perfectly into a busy shop leaving the area around and under it free for other work.

Bagging Machines

The Hiemac Bagmaster is an attractive, compact, machine for bagging garments very quickly and efficiently.

Bagging garments is made easier and quicker as the patented ‘sky hook’ opens and spreads the plastic film as it is pulled down over the garments. With a quick downward snap, the plastic is separated at the hook, leaving the next bag open and ready for the next order of garments.

The Hiemac Bagmaster bagging Machine is best mounted on the slick rail allowing the garments to pass underneath. The ’sky hook’ eliminates the need of a floor stand leaving the floor area around the bagger completely uncluttered.

Automated RFID Garment Sortation

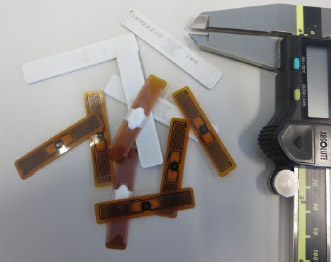

Garments directly from the presses or steam tunnel can be sorted continuously and automatically into any one of 60 sortation rails. Without any operator input the garments move along the screw conveyor, through the RFID reading station. The control computer then directs each garment to its dedicated sortation rail. Each garment has a sewn in indestructible RFID tag capable of hundreds of high temp washers, the tag is also used for garment identification, the essential component in good inventory control .

Automated RFID reading station tagged garments are identified as they pass through this RFID antenna station. The computer then directs them to any one of 60 sortation rails further along the screw conveyor

Pneumatic gates takes the garments off the screw conveyor and directs them down their designated sortation rail.

Steam tunnel with a Hiemac screw conveyor take off with a hanger turn around device.

RFID identification tags

Speed Rail canvas carriers are ideal for carrying folded textiles. They fold up flat when not in use.

With labour being singularly the most expensive cost to production today, your laundry must be continually looking for ways to increase productivity. When it comes to garment handling Hiemac have the equipment, the experience and the knowledge to help.

“The apparel handling specialists”

The Hiemac head office and 1600 square meter factory is located at Thornbury Victoria. Fitted out with the latest engineering equipment and a modern computerized design center, the factory is staffed by a close knit talented group of engineers, tradesmen and professional people. All dedicated in presenting quality and efficiency in everything they produce.;